Frequently Replaced UH 60 Parts and Their Functions

Frequently Replaced UH 60 Parts and Their Functions

Blog Article

The Value of Appropriately Sourcing UH-60 Components for Safe and Reliable Operations

The relevance of correctly sourcing UH-60 parts can not be overstated, as the integrity and safety of aviation operations pivot on the high quality of these elements. Utilizing certified parts not just ensures conformity with strenuous design criteria yet also alleviates the dangers linked with subpar choices.

Comprehending UH-60 Part Specs

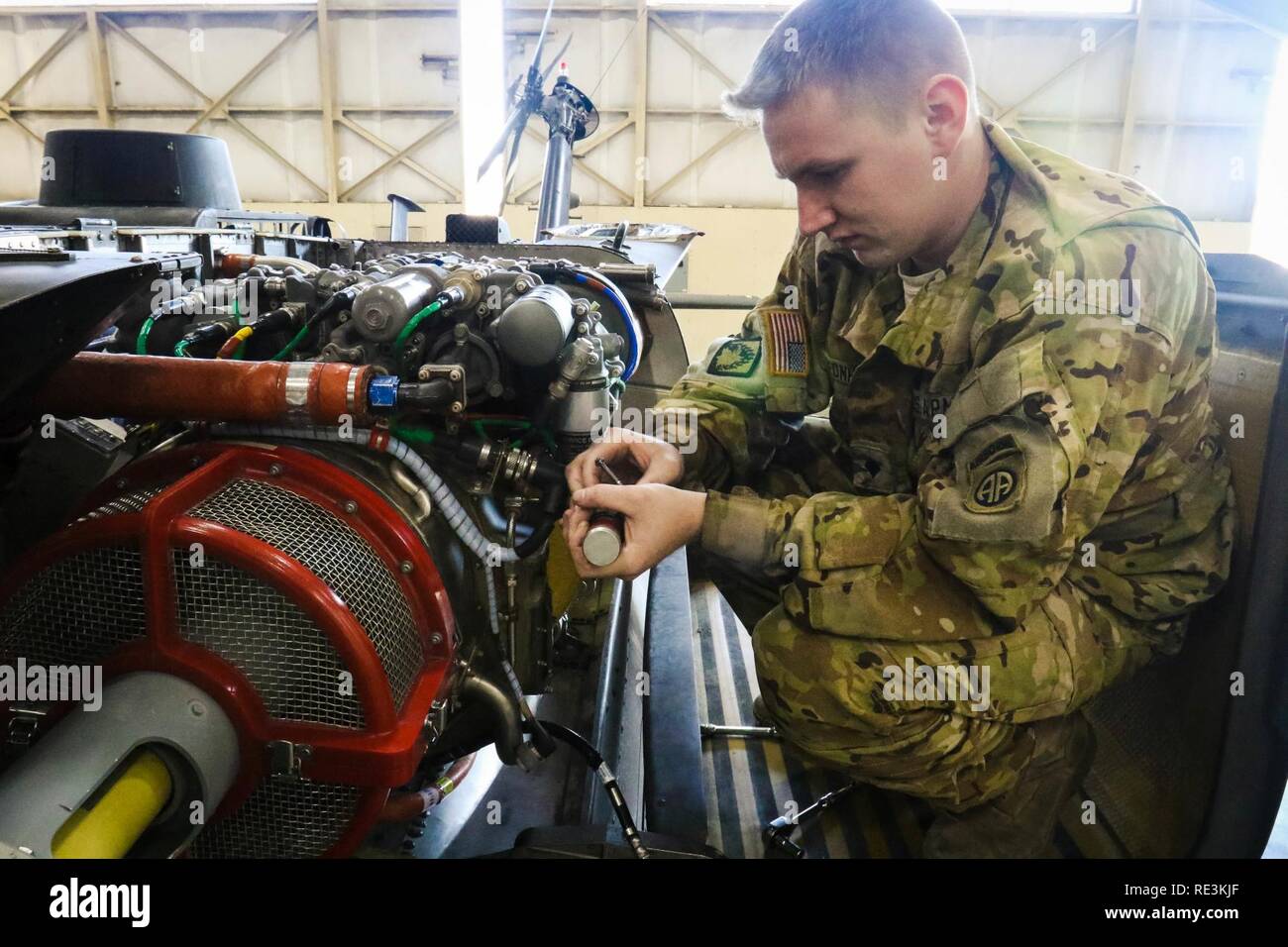

Recognizing the complexities of UH-60 part requirements is essential for making certain functional efficiency and security in aeronautics upkeep. The UH-60, extensively utilized in army and civilian applications, calls for parts that satisfy rigid engineering and regulatory requirements. Each component is diligently developed to execute under details problems, and deviations in specs can cause efficiency failings or safety risks.

Part specifications incorporate numerous qualities, including material structure, dimensional tolerances, and operational limits. As an example, rotor blades need to follow precise weight and aerodynamic accounts to ensure ideal trip attributes. Additionally, parts should undertake rigorous screening to verify their reliability and toughness within the requiring environments common of air travel operations.

Moreover, comprehending the accreditation processes related to UH-60 components is important. Each part may bear markings indicating conformity with army or industry criteria, ensuring that it has undergone the essential examinations and quality analyses. This compliance not just safeguards the airplane's performance yet likewise promotes accountability amongst makers and providers. For that reason, extensive understanding of component requirements is vital for maintenance personnel, allowing them to identify genuine components and keep the operational integrity of the UH-60 fleet.

Risks of Making Use Of Substandard Parts

The honesty of aviation procedures pivots on the high quality of parts used in aircraft maintenance, particularly for the UH-60. Utilizing second-rate parts postures considerable dangers that can endanger both safety and functional effectiveness. These elements might not satisfy the strenuous criteria developed for military aeronautics, leading to unpredictable efficiency and potential system failings.

Substandard parts can result in boosted deterioration on vital systems, inevitably shortening the life expectancy of the aircraft and requiring pricey repair services or replacements. Additionally, using inferior products might lead to devastating failings during trip, jeopardizing the lives of staff members and guests alike.

Furthermore, reliance on non-compliant elements can subject operators to legal and governing repercussions, as aircraft needs to follow strict guidelines stated by governing bodies. This can lead to grounding of the aircraft and substantial functional hold-ups.

Advantages of Licensed Parts

Licensed components offer a wide range of benefits that dramatically boost the security and integrity of UH-60 procedures - uh 60 parts. One of the main advantages of these components is their adherence to rigorous high quality standards. Accreditation procedures make sure that each component has actually gone through rigorous testing and assessment, thereby validating its performance and sturdiness under various operational conditions

The combination of certified components additionally promotes smoother maintenance procedures. Professionals can be positive in the integrity of these parts, reducing the possibility of unintended fixings and boosting overall blog functional efficiency. The long-term cost-effectiveness of qualified elements can not be overemphasized; while they may come at a greater first rate, their integrity and efficiency convert into lower upkeep and substitute costs over time. Eventually, purchasing licensed elements is crucial for the risk-free and reliable procedure of UH-60 aircraft.

Sourcing From Trusted Providers

When sourcing components for UH-60 aircraft, partnering with respectable vendors is crucial to ensuring top quality and integrity. The security and performance of armed forces airplane depend considerably on the honesty of their parts, making it critical to choose providers with a tried and tested performance history in the industry. Credible suppliers stick to strict quality assurance steps and usually hold relevant certifications, which work as a testimony to their dedication to quality.

Along with high quality assurance, developed providers offer extensive assistance services, including technical assistance, warranty programs, and timely distribution. This level of involvement is vital for keeping functional preparedness and decreasing downtime. Trustworthy distributors are usually a lot have a peek here more transparent concerning their sourcing techniques, making certain that the components provided satisfy stringent governing criteria and are suitable with existing systems.

It is likewise valuable to consider vendors who specialize in UH-60 components, as they possess extensive understanding of the aircraft's specs and requirements. By leveraging the knowledge of these providers, operators can improve the safety and efficiency of their procedures, inevitably resulting in improved goal success. Spending time in sourcing from credible distributors is an essential action toward achieving optimum performance in UH-60 aircraft procedures - uh 60 parts.

Long-Term Price Effectiveness

Attaining lasting cost efficiency in sourcing UH-60 parts needs a critical strategy that stabilizes preliminary financial investment with continuous functional costs. Organizations needs to prioritize quality over cost, as substandard parts may cause frequent repairs and enhanced downtime, eventually pumping up total costs. By spending in dependable, licensed components, drivers can improve the airplane's efficiency and durability, alleviating the risk of unanticipated failures.

In addition, establishing long-term relationships with trustworthy suppliers can generate financial advantages, such as bulk additional reading investing in discounts and positive settlement terms. These partnerships promote access to remarkable products and technical support, ensuring that the sourcing procedure aligns with operational requirements and governing standards.

Moreover, applying a systematic supply monitoring method enables for better projecting of part requirements, reducing excess supply and associated holding prices. On a regular basis examining supplier efficiency and part dependability can likewise notify future acquiring decisions, allowing companies to adapt to progressing functional demands successfully.

Inevitably, a concentrate on long-lasting cost efficiency in sourcing UH-60 parts not only safeguards functional stability however also contributes to an extra lasting financial version, permitting reinvestment in crucial aviation capabilities.

Verdict

In final thought, the proper sourcing of UH-60 parts is crucial for maintaining reliable and safe air travel operations. Sticking to rigorous requirements and using certified parts reduces the risks connected with substandard parts.

The significance of effectively sourcing UH-60 parts can not be overstated, as the integrity and safety of air travel operations pivot on the top quality of these components.Understanding the details of UH-60 component specifications is essential for making certain operational effectiveness and security in air travel maintenance. Thorough expertise of part specifications is vital for maintenance workers, enabling them to recognize genuine elements and keep the functional honesty of the UH-60 fleet.

When sourcing components for UH-60 aircraft, partnering with reputable providers is critical to guaranteeing top quality and dependability.Achieving lasting expense effectiveness in sourcing UH-60 parts calls for a calculated strategy that stabilizes initial investment with continuous operational expenses.

Report this page